PERSONAL PROTECTIVE EQUIPMENTS POLICY

Ref No: NMHL/LOG/PO/004

Rev No: 0

PERSONAL PROTECTIVE EQUIPMENTS POLICY

INTRODUCTION

New Muthokinju Hardware Limited is committed to providing a safe working environment for all its staff, business associates and visitors. NMHL aims at providing safe work places and systems of work, empower employees and contractors to address unsafe or hazardous situations and carry out their work in a manner that does not present a risk to themselves, others or the environment. Personal protective equipment will be provided, used, and maintained when it has been determined that its use is required to ensure the safety and health of our employees and that such use will lessen the likelihood of occupational injury and/or illness. PPE is not a substitute for more effective control methods and its use will be considered only when other means of protection against hazards are not adequate or feasible.

PURPOSE

The purpose of this policy is to protect the employees of New Muthokinju Hardware Limited from exposure to work place hazards and the risk of injury through the use of personal protective equipment (PPE).

SCOPE

This Policy applies to all NMHL employees, contractors and casual workers within NMHL premises

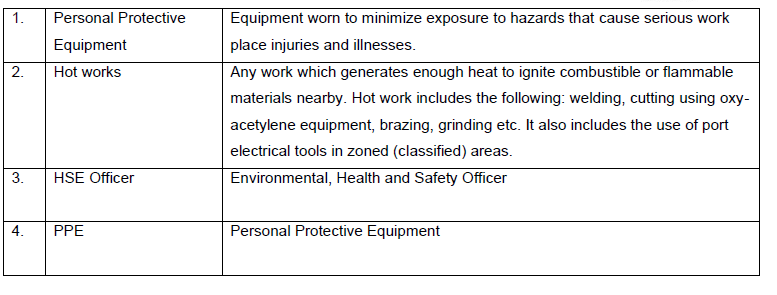

DEFINITIONS

RESPONSIBILITIES

Environmental Health and Safety Officer

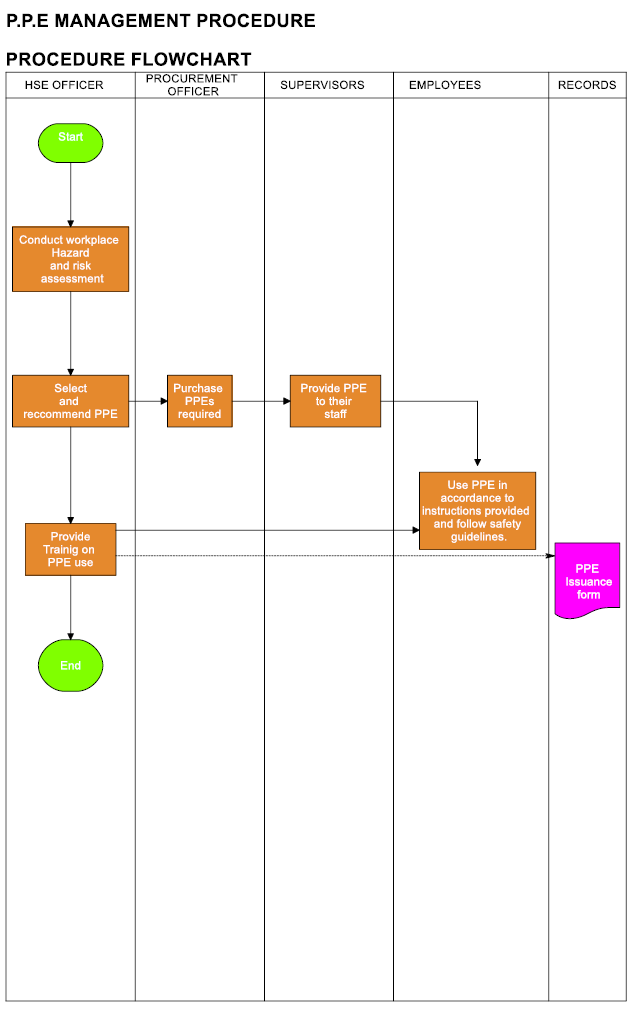

Conducting workplace hazard assessments to determine the presence of hazards which necessitate the use of PPE.

Selecting and recommending for purchasing of PPE.

Reviewing, updating, and conducting PPE hazard assessments whenever a job changes, new equipment is used, there has been an accident, a supervisor or employee requests it and/or at least every year

Maintaining records on hazard assessments.

Maintaining records on PPE training.

Providing training, guidance, and assistance to supervisors and employees on the proper use, care, and cleaning of approved PPE.

Periodically re-evaluating the suitability of previously selected PPE.

Reviewing, updating, and evaluating the overall effectiveness of PPE use, training, and policies.

Supervisors

Supervisors have the primary responsibility for implementing and enforcing PPE use and policies in their work area.

Providing appropriate PPE to employees.

Ensuring that employees are trained on the proper use, care, and cleaning of PPE.

Ensuring that employees properly use and maintain their PPE, and follow NMHL PPE policy and regulation.

Notifying management and the HSE Officer when new hazards are introduced or when processes are added or changed.

Ensuring that defective or damaged PPE is immediately disposed of and replaced.

Employees

Use PPE in accordance with instruction provided and follow established safety guidelines.

Participate in training regarding the appropriate use, care and maintenance of PPE.

Properly caring for, cleaning, maintaining, and inspecting PPE as required.

Informing the supervisor of the need to repair or replace PPE.

Step 1: Hazard Assessment for PPEs

A walk-through survey of each work area to identify sources of work hazards using a Hazard Assessment Form will be conducted.

Appropriate PPE will be highlighted and a Risk Assessment will detail the relevant PPE necessary.

The HSE Officer shall conduct, review, and update the hazard assessment for PPE whenever;

•

A job changes.

•

New equipment or process is installed.

•

There has been an accident.

•

Whenever a supervisor or employee requests it.

Step 2: Selection of PPEs

Hazards identified shall first be determined whether they can be eliminated or reduced by methods other than PPE.

New or additional equipment which ensures a level of protection greater than the minimum required to protect employees from the hazards will be selected.

Recommendations for purchase for adequate protection against the highest level of each of the hazard shall be made.

Types of personal protective equipment

Hand protection

Gloves shall be worn where there is a risk of cuts, abrasions, burns, or exposure to hazardous materials. For most applications, standard leatherwork gloves are recommended.

For special applications, such as working with chemicals, staff shall make sure that the type of glove they wear is resistant to penetration. In such cases, they shall refer to the type of gloves recommended by the manufacturer of the product or check with QHSE.

Eye Protection

Approved safety glasses are required for all tasks presenting a risk of flying objects or dust particles, splashes of hazardous materials or harmful rays. Grinding, cutting, work shop machines, transferring chemicals, welding, drilling, demolishing, are but a few examples of where eye protection is required, and the use of eye protection should not be limited to these areas.

Hearing protection

Earmuffs, earplugs or both shall be worn when working with or near certain noisy tools or machinery like gasoline-powered tools, emergency power generators, or other high-speed cutting and grinding tools.

Head protection

Hard hats that meet the local regulatory standards shall be worn to provide protection from falling objects, flying debris, overhead obstructions and similar hazards to the head. When performing maintenance work involving overhead hazards, for example, under scaffolding or extension ladders, etc.

Foot protection

Industrial footwear that provides protection to the foot against puncture, falling, rolling and crushing hazards, greasy or wet situations shall be worn.

Respiratory protection

Respirators may be required in certain situations involving the release of hazardous materials into the air that cannot readily be controlled by way of ventilation.

- Before performing any work requiring a respirator, staff must first

ascertain that the type of respirator they are using is the correct one and that

they have been properly fitted to make sure it works efficiently. - Simple disposable dust respirators may be used without specialized training provided the dusts in the atmosphere are not considered to be at toxic levels.

Protective clothing

Protective clothing may be required for body/skin protection among other hazards, examples include coveralls, vests, jackets, aprons and full body suits.

Specialized PPEs

Special purpose PPE shall be used for protection against certain unique hazards including doing high risk activities e. g hot works, working at height and working in confined spaces.

Step 3: Acquisition of PPE

The recommended PPE for specific tasks shall be purchased by the Procurement Officer.

Step 4: Training

All workers shall be trained in the proper use and care of PPE before being allowed to perform work requiring their use. The training includes, but not necessarily limited to, the following:

- What PPE is necessary?

- When PPE is necessary to be worn.

- How to properly wear PPE.

- The proper care, maintenance, useful life, and disposal of the PPE.

Refresher training

The need for re training will be indicated when;

- An employee’s work habits or knowledge indicate a lack of necessary understanding and skills required to use the PPE.

- New equipment is installed.

- Changes in the work place make previous training out of date.

- Changes in the types of PPE to be used make previous training out of date.

This shall be documented using the Personal Protective Equipment Issuance Form and kept in the HSE file.

The document certifies that the employee has received and understood the required training on the specific PPE he/she will be using.

Step 5: Providing PPE to Employees

- Employees shall be provided with PPE accordingly by their supervisors. Careful consideration will be given to the proper fit and comfort of PPE.

Step 6: Cleaning and Maintenance of PPE

- All PPEs shall be kept clean and properly maintained.

- Employees shall inspect, clean, and maintain their PPE according to the manufacturers’ instructions before and after each use.

- Supervisors shall responsible for ensuring that users properly maintain their PPE in good condition.

- Defective or damaged PPE shall be replaced and discarded accordingly.

Stop Work

Individuals who do not comply with this policy should be stopped from proceeding with the work until all safety procedures are adhered to.

Safety Disciplinary Guideline

In order to maintain a safe and healthy workplace, the employees must be knowledgeable and aware of all safety and health regulations as they apply to their specific job duties. The following disciplinary policy is in effect and will be applied to all safety violations.

The following steps will be followed unless the seriousness of the violation would dictate going directly to Step 2.

For a first time violation, this will result to a written reprimand.

A second time violation, a sitting with senior management with a guaranteed time off or possible termination, depending on the seriousness of the violation.

Measurement of Effectiveness

- The percentage of employees who use PPE properly during occupational activities (validate the fit checking of PPE), 100% conformance.

- Ensure 100% complete training on PPE use and maintenance.